Overcoming the strength-ductility trade-off and anisotropy of mechanical properties of Ti6Al4V with electron beam powder bed fusion

Jiayin Li, Xiaotao Liu, Xuan Luo, Fei Gao, Chao Zhao, Bowen Ma, Dongdong Li*, Chao Yang

https://www.sciencedirect.com/science/article/pii/S0921509323007256

Abstract

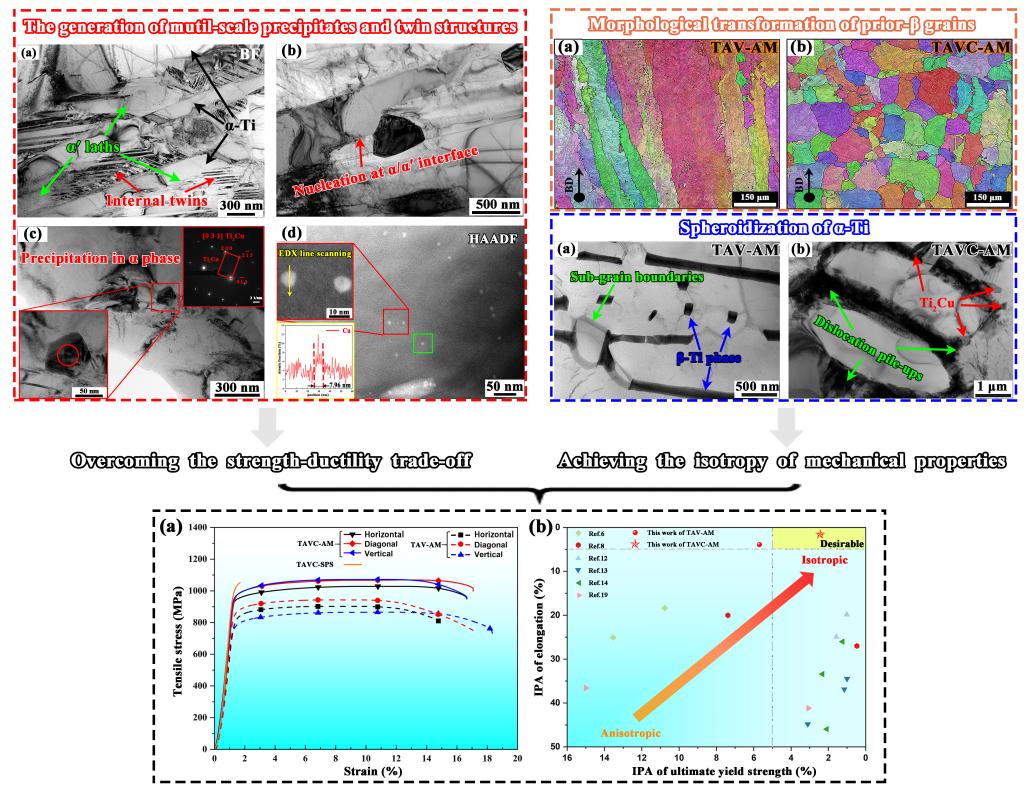

Achieving a combination of excellent ductility and mechanical property isotropy is highly desirable for conventional biomedical materials, although this has been a long-standing problem. Here, we present a novel approach, in situ alloying of Cu (3.5 wt%) into Ti6Al4V through electron beam powder bed fusion (EB-PBF), through which the aforementioned issues can be addressed. The ultimate tensile strength (UTS) and elongation (EL) to failure of the Ti6Al4V-3.5Cu (TAVC) alloy fabricated by EB-PBF were found to reach values of 1053 MPa and 15.3%, respectively, which are markedly superior to those of the PBF-EB/Ti6Al4V (UTS: 902 MPa; EL: 13.5%). However, an alloy with identical composition made by spark plasma sintering exhibited a significant brittleness characteristic (UTS: 1051 MPa; EL). Moreover, the generation of multiple micro/nanosized Ti2Cu phases (1–5 μm, 50–100 nm, and 5–10 nm) in the TAVC alloy samples is thought to contribute a significant strengthening (46.24%), which effectively prevents plastic deterioration caused by brittle lamellar (Ti2Cu + α-Ti) structures. Further investigation revealed that the ductile enhancement of the TVAC alloy can be attributed to the microstructural evolution that encompasses the generation of twin structures and spheroidization of α-Ti and results from the addition of Cu coupled with the intrinsic heat treatment during the EB-PBF manufacturing process. Our findings not only provide an in-depth understanding of the formation mechanism of multi-scale Ti2Cu precipitates but also offer critical guidance for improving the overall mechanical properties of Cucontaining biomedical titanium alloys.